Hydraulic Flow divider

A hydraulic flow divider is a device used in hydraulic systems to divide a single flow of hydraulic fluid into multiple flow streams while ensuring that each output stream receives a proportionate amount of fluid. It is used to achieve balanced flow distribution to various parts of a system, often for driving multiple actuators, hydraulic motors, or other hydraulic devices simultaneously in an efficient and controlled manner.

Main Function of a Hydraulic Flow Divider:

The primary function of a hydraulic flow divider is to split the hydraulic flow into two or more separate, but proportionally controlled, streams. This ensures that each downstream branch receives the appropriate amount of fluid, regardless of variations in load or pressure. Flow dividers are particularly useful when different hydraulic components or actuators require different amounts of fluid but need to be powered simultaneously.

Working Principle:

Hydraulic flow dividers operate based on the principle of positive displacement, where the same amount of hydraulic fluid that enters the divider must exit through the divided streams. Here’s a simplified process of how a hydraulic flow divider works:

- Fluid Entry: Hydraulic fluid enters the flow divider from the pump or another part of the system.

- Flow Splitting: Inside the flow divider, there are mechanisms such as gears, spools, or vanes that divide the incoming flow into two or more separate output streams. These mechanisms ensure that each output receives a precise amount of fluid based on the design of the flow divider.

- Balanced Flow Distribution: A hydraulic flow divider ensures that the flow is evenly or proportionally distributed to multiple outputs, such as hydraulic cylinders or motors. Some flow dividers also maintain this balance despite changes in pressure or load, which is crucial in maintaining smooth operation across the system.

- Pressure Compensation: In some advanced designs, hydraulic flow dividers include a pressure compensation feature. This ensures that the flow is adjusted dynamically in response to load changes, keeping the division of flow balanced even if the pressure in the system varies.

Types of Hydraulic Flow Dividers:

- Fixed Flow Dividers:

- These split the flow into a fixed ratio, such as 50/50, 60/40, etc., regardless of changes in pressure or load. They are simple and inexpensive but may not be as flexible when the system experiences varying load conditions.

- Proportional Flow Dividers:

- These allow the flow to be split in adjustable or variable proportions based on the needs of the system. For example, the system might need to split 70% of the flow to one actuator and 30% to another, and the flow divider adjusts based on system demands.

- Pressure Compensated Flow Dividers:

- These dividers are designed to compensate for pressure changes. When the load on an actuator increases, the flow divider adjusts to ensure that each actuator still receives the correct flow, even if the pressure varies. This ensures consistent operation and prevents one actuator from receiving too much or too little flow.

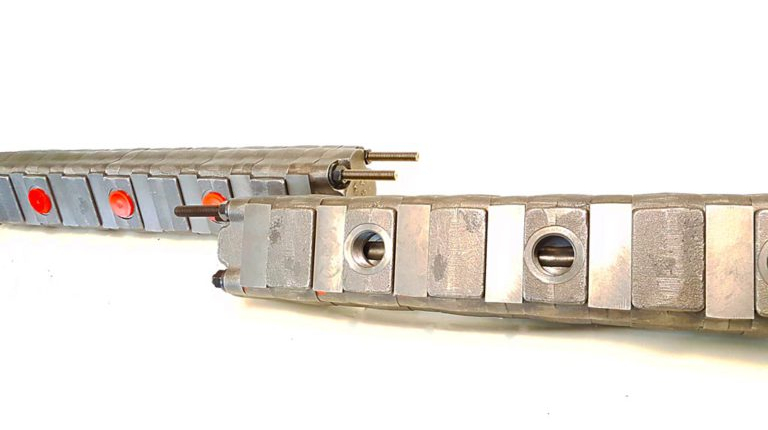

- Rotary Flow Dividers:

- These are mechanical flow dividers that use gears or vanes to divide the hydraulic flow into multiple streams. They often provide a more precise and balanced flow split but can be affected by wear over time.

Applications of Hydraulic Flow Dividers:

Hydraulic flow dividers are used in various industries and applications where multiple hydraulic devices or actuators need to operate simultaneously and receive consistent fluid distribution. Some common applications include:

- Construction Equipment: In machinery like backhoes, excavators, and cranes, where multiple cylinders or motors need to be powered in sync, such as moving the arms, lifting components, or rotating the structure.

- Agricultural Equipment: In tractors or harvesters, where hydraulic systems are used to control various implements such as loaders, mowers, or seeders, and the flow must be divided to ensure the proper operation of each function.

- Material Handling: In systems such as conveyors, winches, or hoists, hydraulic flow dividers ensure that the flow is equally or proportionally divided to move different parts of the system simultaneously.

- Hydraulic Steering Systems: In vehicles, flow dividers are often used to ensure that hydraulic fluid is evenly distributed between the steering mechanism and other hydraulic components, such as the lift or drive system.

- Industrial Machinery: In systems requiring the simultaneous operation of multiple hydraulic actuators, such as in robotics or automated production lines.

Advantages of Hydraulic Flow Dividers:

- Flow Balance: Flow dividers ensure that multiple components in a hydraulic system receive the appropriate amount of fluid, which helps maintain system efficiency.

- Synchronization: In systems requiring synchronized movement (e.g., lifting multiple parts of a machine), a flow divider ensures that each component operates in unison.

- Pressure Compensation: Some flow dividers automatically adjust to pressure variations, ensuring that the flow division remains balanced even under different loading conditions.

- Versatility: Flow dividers can be used in a wide variety of applications, from heavy machinery to more delicate equipment that requires precise flow control.

- Prevents Overloading: By accurately dividing the flow, hydraulic flow dividers prevent one part of the system from receiving too much fluid (and thus being overloaded) while others are deprived.

Limitations:

- Complexity and Cost: Some advanced types of hydraulic flow dividers, especially those with pressure compensation or proportional flow control, can be more complex and expensive than simpler, non-compensated models.

- Maintenance: Flow dividers with mechanical components, such as gears or vanes, may wear out over time and require maintenance or replacement.

- Flow Limits: Flow dividers have limitations on how much flow they can handle, which means they may not be suitable for systems with very high flow requirements unless designed specifically for that purpose.

Conclusion:

A hydraulic flow divider is a crucial component in hydraulic systems that need to distribute hydraulic fluid to multiple parts or actuators. It ensures that the fluid is divided accurately and proportionally, maintaining balanced operation across the system. Whether used in construction machinery, agricultural equipment, or industrial applications, hydraulic flow dividers help improve efficiency, prevent overloads, and ensure smooth, synchronized movement in systems requiring multiple hydraulic functions.